TANK

CLEANING

- Chemical / Food-grade

- Baffle / Multi-Compartment

- Liquid Cargo Steam Heating

- Liquid Cargo Break Bulking

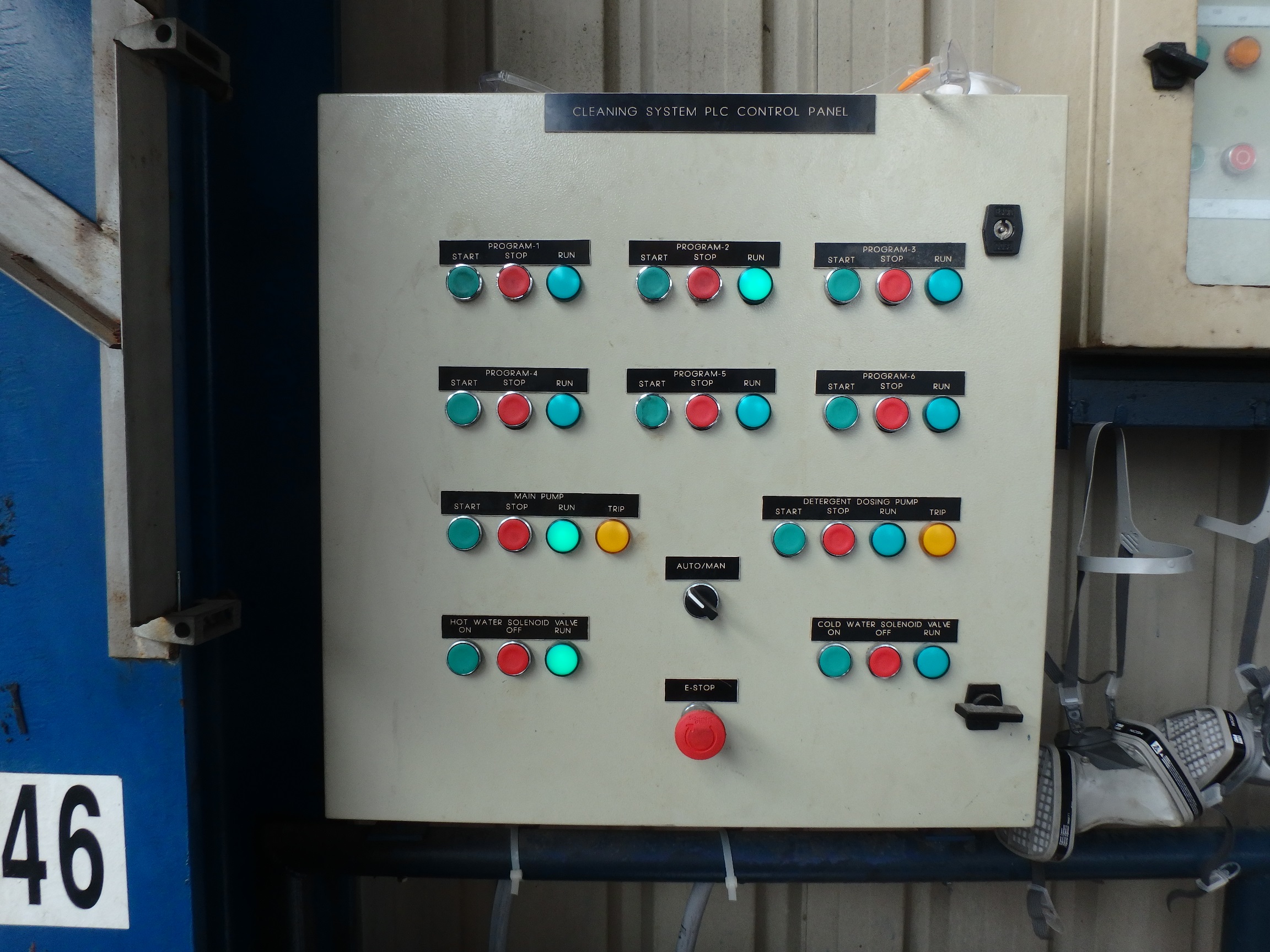

Automatic Tank Cleaning Programming System

Our tank internal cleaning and residue disposal methods are highly efficient, with the aid of our high performance Automatic Tank Cleaning Programming System, controlled by a PLC 24 hours daily. We are able to thoroughly clean 4 tanks or multi-compartment tanks at the same time, with 2 or 4 rotary cleaning heads, maximizing efficiency, and using minimal time. We are using 100-bar high pressure plunger pump to clean all kinds of food grade or chemical last cargo.

All SDS and previous tank history are being recorded into the Tank Cleaning Recording Kiosk, a part of our Integrated Depot Management System (IDMS), which we are able to monitor and record on the cleaning methods and time required to clean each individual last cargo, and analyse on the performance of our tank cleaning operators, to improve our own cleaning speed and capabilities.

Bio-Reactor Waste Water Treatment System

We have also invested in Green Technology – Our modified Bio-Reactor Waste Water Treatment System. The system enables us to treat waste water, reducing it to a neutral level with our treatment pits before drainage. All our depots have been upgraded, being equipped with the Ultra-Filtration, Nano-Filtration, Reverse Osmosis and DAF (Dissolved Air Flotation) System , cotac ITS is promoting high environment responsibility to our countries.